It’s 6 a.m.

While many might just be waking up or hitting “Snooze,” Colby Phillips is already putting in the hours, checking his email at US Whip HQ.

6 a.m. is quiet. 6 a.m. is when he can focus.

6 a.m. is when he can reflect on the 30 years he’s invested in helping our company become the livestock training industry’s bar to top.

In an era when job hopping to chase bigger salaries and fancier titles is common, his longevity could be considered a rarity. But as he explains, “When you work for good people—people that care about their employees—it makes it easier. I wanted to be promoted within the company and work my way up.

It doesn’t hurt that we eat good around here, either.”

From Picking Up Rocks to Rockstar Employee

Like a lot of boys growing up, Colby wanted to be a lot of things: A doctor, a cop or firefighter — all honorable careers requiring a second-to-none work ethic.

So in 1993, when Kay, daughter of US Whip founder Clark Bowman, overheard Colby say he was looking for a job while they were both getting their hair cut at a local salon, she suggested he apply.

He interviewed with Clark, who hired him on the spot. And Colby started from the ground up.

Literally.

“Our buildings are set off from the highway and we have about an eighth-of-a-mile rock driveway, so my first job was picking up bigger rocks to prevent flat tires. I mowed, trimmed weeds, swept floors and took out the trash,” he recalls.

After graduating high school, Colby continued to learned the ropes: From production to shipping—all the way up to the Production Supervisor role (where he learned firsthand the intricate manufacturing process of our handmade horse whips) taking on a new challenge in our sales department.

That’s nine different roles in total. Today, he’s responsible for helping expand our business.

Lessons Learned (and Taught)

Colby’s career at US Whip has been guided, professionally and personally, by hands-on instructors, none more important than Clark, who served as a mentor.

“From day one I learned so much from him, and not just the whip business. Over the years we have built out much of the interiors of our buildings ourselves: Walls, electric, plumbing. Eventually, I carried those learning experiences over to my personal life,” Colby recounts. “He even showed me how to dress out a deer and process it.”

Now that he’s in sales, Colby’s looking to pay forward the same career-advancing guidance he’s received over the years. When asked what he would tell anyone who is serious about investing in their career, he said dependability and patience are key (but he admits to still working on the latter).

For aspiring salespeople, he says, “Communication is so important, especially communicating your product knowledge: How’s it’s used, why it’s better than the competitors, what those standout benefits are.”

You’ll see Colby’s eyes light up when he does just that at trade shows, selling product while meeting with distributors and vendors.

How Things Change

When Colby started here, we had one 40’x80’ building. Now, we’ve added a warehouse and a 60’X90’ space which he helped create.

He’s also served an integral role in improving our whip making process.

When asked about the changes he’s seen in the livestock industry since he started, Colby gave thoughtful insight.

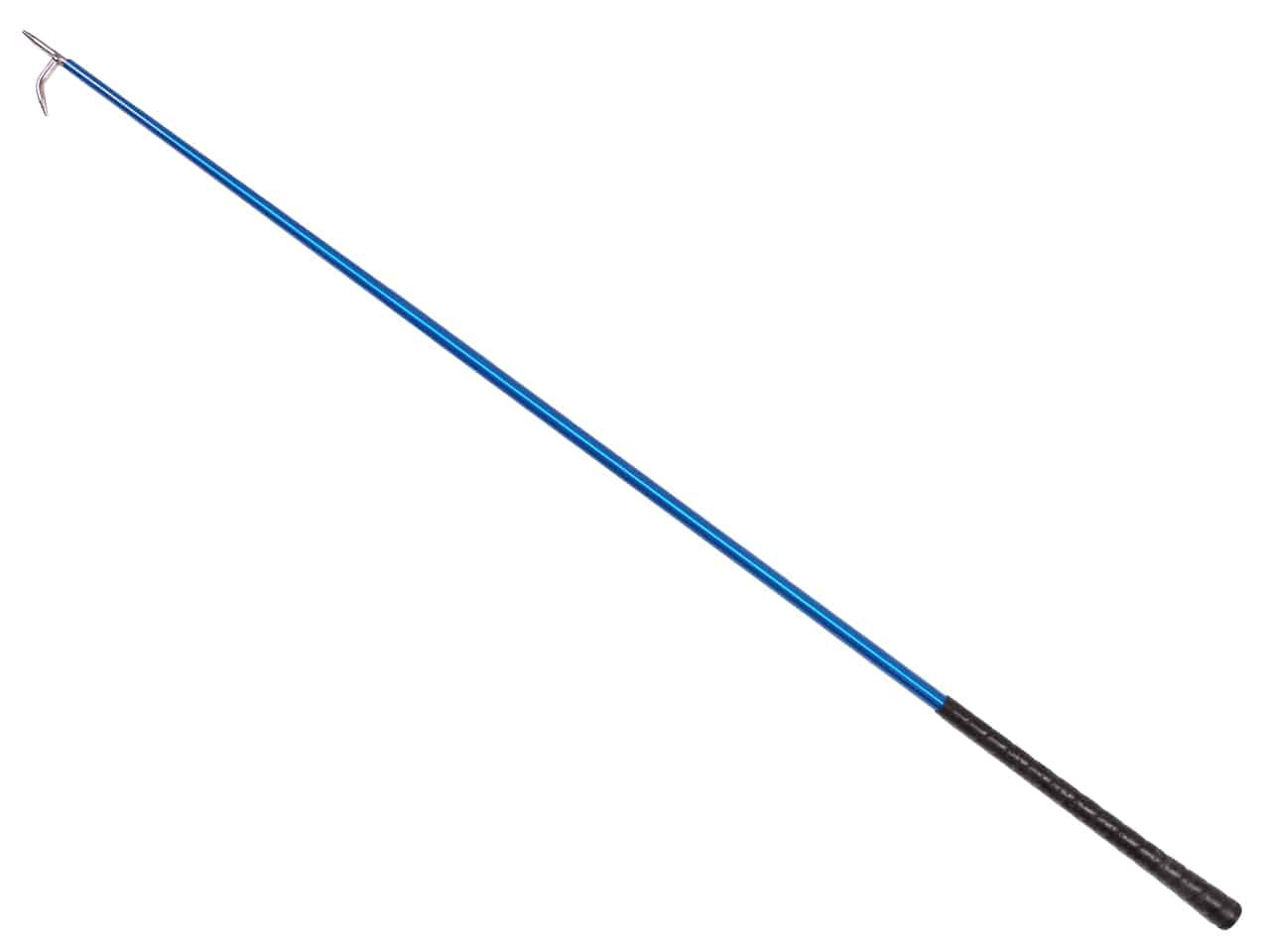

“Beef and hog production has grown tremendously. Ranches across the country have grown much, much larger and they’re utilizing new technologies to manage huge herds at scale. These ranchers are using our sorting poles, flags whips and rattle paddles to work their cattle and hogs.

The show animal industry has grown as well. I can’t even begin to tell you how many 4H, FFA, county fairs, jackpots and major livestock shows there are across the country every year. It’s very competitive. And that directly relates to our business. These kids are using our show sticks to show cattle and pig whips for showing pigs.”

The next 30 years will prove to be just as defining — and Colby recognizes the opportunity.

“Livestock isn’t going to change, but the technology that helps manage them will, hopefully for the better. We’re constantly trying to lean into that technology to make our manufacturing more efficient, while still holding true to the handmade quality we’re known for.”

Up Next

Colby’s proud of many of his accomplishments during his tenure here, none more than helping integrate Wonder Whip into our umbrella of products when we acquired them.

Even after three decades, he’s still motivated by thinking of new products or finding that one little idea that could get our products in the hands of more livestock owners that he hasn’t given retirement any real thought.

But when the time comes?

“I’ve really gotten into BBQ the past year or so. I bought a smoker. I love it, it relaxes me. I think it would be cool to have a little concession trailer and sell pulled pork, bologna sandwiches and my mom’s potato salad.”

See?

Even during retirement, Colby would wake up at 6 a.m.

And that’s why we hope he sticks around here for another 30 years (if he wants to).