Processing and working with cattle is made much easier when a rancher’s cattle handling facility is designed well. The size and type of facility depends on the operation in question, yet each will have some common design elements involved. Let’s explore this topic more by discussing low-cost cattle handling facility design.

Purposeful Design

Cattle handling facilities are designed with the purpose of moving the animals into a squeeze chute or for loading them into a truck; either way, they consist of some main elements:

-

- Holding pens

- Alleys

- Crowd pens

- Working and Loading Chutes

The amount of cattle being processed, the area of the cattle handling facility, and the preferences of the rancher, all factor into how exactly these main elements are constructed. Open side panels are the standard for the facility, except for rounded crowd pens and chutes with some facilities; portable side panel facilities with a Bud Box are open.

The main purpose is to design and build a facility to move the cattle smoothly, efficiently, and safely. The good new is: achieving this purpose doesn’t require spending a lot of money, it can be simple cattle handling designs.

Location of the Facility

Many cattle handling facilities are permanently built in areas where cattle can be herded in from adjacent fields and loaded into trucks; proximity to electricity, water, food, and shelter also dictate where cattle handling facilities are constructed.

Portable cattle handling facilities can be built up and taken down after processing the cattle; constructed with open metal side panels, these low-cost cattle handling facilities use a Bud Box to flow the cattle into the chutes (see last section). These can be set up adjacent to an already established chute or holding pen – whatever the situation requires.

The main considerations are to set up a facility with:

-

- good drainage

- good surface materials

- adequate air flow

- good proximity to fields and roads

- access to electricity, food, water, shelter

- enough distance away from unnecessary distractions.

The choice of location is even more important if a permanent cattle handling facility is being constructed, rather than a portable facility with movable side panels.

Design of the Facility

Again, constructing and designing an cattle working facility layout doesn’t have to cost a lot of money; being resourceful and using a simple design will lower the overall costs. According to an article on Drovers called: “Tips to design low-cost cattle handling facilities”, we learn:

“Johnson owns 70 head of docile Red Angus cattle and could handle more with his facility. He estimated his cash costs at about $1,500 for the used items such as AI chute and head gate, corral panels or gates, cattle panels, headlocks, and T-posts and miscellaneous materials.”

When it comes to the actual size of the facility, an article on Progressive Cattleman called: “Easy steps to designing cattle-handling facilities”, written by Deke Alkire on December 24th, 2012, explains:

“It is generally recommended that holding pens provide 20 square feet per cow and 14 square feet per calf.”

When it comes to the alleyways, 12 feet wide is recommended; the crowding pen should be around 10 ft in diameter for curved tubs, and 14′ x 20′ for a Bud Box. The curved crowding pens are designed to make the cow feel as if they’re turning around to go back, yet instead are feed into the chute; the Bud Box, instead of being curved, simply allows the cows the space to turn around and into the chute.

Consider a Bud Box

The most costly elements of a cattle handling facility are the crowding pens and chutes. Loading chutes gradually incline for around 12 ft until they are 4 ft high, and the working chute is long enough to hold a handful of cattle at once with a headlock at the end. The Bud Box is simply a square version of the curved crowding pen.

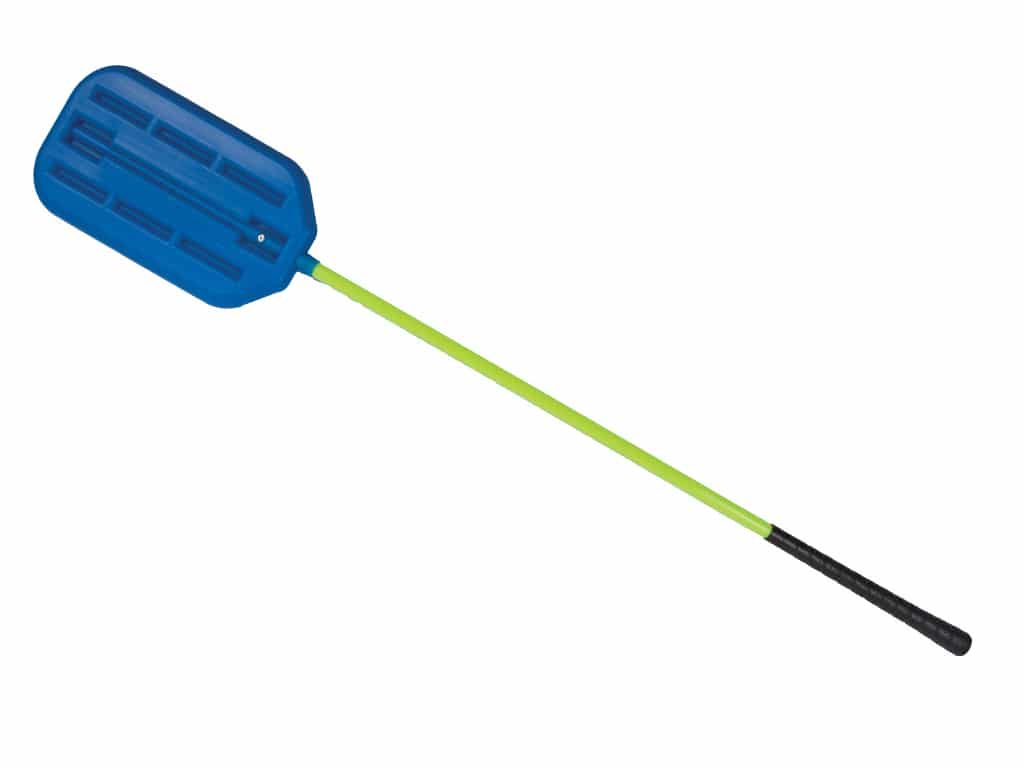

The Bud Box is cost-effective because it doesn’t require any curved construction; open square metal panels can be set up to construct the Box. This term is derived from the name of the designer: livestock handling expert Bud Williams. The purpose of the Box is to use the natural desire of the cattle to turn around to feed them into the chute — a low stress method.

The Bud Box is explained well in an article found at On Pasture called: “Build a ‘Bud Box’ to Make Livestock Handling a Brdeseeze”, written by Rick Machen and Ron Gill, which also has a bud box cattle handling youtube video illustrating how a portable cattle handling facility can be use with a Bud Box – check it out.

Summary

In order to know how to design a low-cost cattle handling facility, ranchers must be resourceful and use a simple and purposeful design. Utilizing the natural movements of the cattle and choosing an optimal location for the facility are two of the main factors to consider for effectiveness; as for cost-savings: implementing a Bud Box, using a portable side panel facility, and/or constructing the facility with used materials, are great ways to be economical.